Sending your design to a print bureau

If you’re planning to use a bureau to print your design, you could just send over your CAD model in a neutral file format like STEP, 3MF or STL. However, when translating your file to the actual gcode that will drive the 3d printer, the bureau will choose the values of different variables that will affect the final part properties, so we recommend you try and specify as many of those as you can. There are also post-processing steps to consider that will affect your final part quality. Specifying what you require at each step will help you get as close as possible to your expected result.

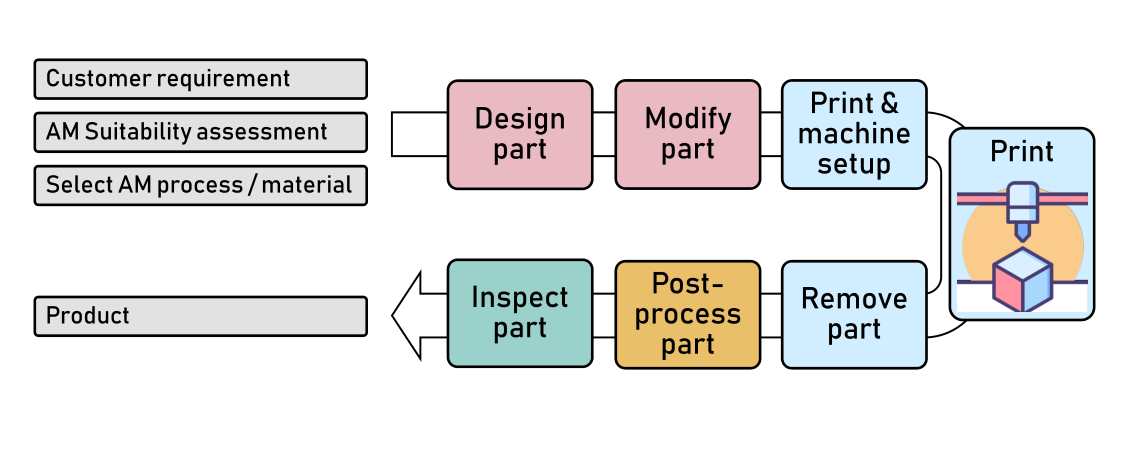

3DP workflow (MakeAmaze)

For a MEX part, these are parameters to consider specifying when you upload your CAD model:

|

Stage |

Variable |

What it affects in the final part |

How to define it |

|

Build layout |

Orientation |

Amount of support material, surface texturemechanical properties (see BP033). Note that this also affects build time and therefore, cost. |

Send instructions to use the part’s orientation as supplied |

|

Supports |

Where to permit supports, what type (tree etc). |

Send a 3MF file that includes your part and the supports as separate items |

|

|

Slicing |

Nozzle diameter |

Resolution of sharp corners, wall thickness (number of passes needed), minimum/maximum layer height. A bureau may favour a large nozzle for speed, but you may a small nozzle for definition. |

Indicate the minimum feature resolution you need and the required tolerance, to ensure the correct nozzle size is used.. Bear in mind that loaded filaments such as wood, CF or GF filament may require a large nozzle, e.g. 0.8mm |

|

Layer thickness |

Vertical resolution (stepping), surface texture. Note that this also affects build time and therefore, cost. |

Request a specific layer thickness |

|

|

Wall thickness |

Part strength Note that this also affects build time and therefore, cost. |

Specify a minimum number of inner shells |

|

|

Infill |

Part strength Note that this also affects build time and therefore, cost. |

Specify the infill percent (and pattern if you know the slicer that will be used) or indicate that the part needs to be mechanically strong. If the bureau agrees, you could even use your own slicer to create a gcode file and send that, for the bureau to use as a reference. |

|

|

Post-processing |

Support removal |

You may want the part shipped with supports attached. |

Indicate if you want supports removed or you prefer to do it yourself |

|

Heat treatment |

Thermally treating some materials (eg PLA) can improve their mechanical properties. |

If the bureau does provide this service, there should be a number of standard treatments to choose from. Otherwise it may need to be done inhouse. |

|

|

Vapour smoothing |

Vapour smoothing improves texture and even water tightness of the part, but can adversely affect the mechanical properties if not done correctly. More information here |

If the bureau offers this process, then you should first discuss the expected loss of detail/ dimensional changes to the part. |

|

|

Plating/coating |

Plating or coating can change the appearance and function of the part, for example electroplating would make the part electrically conductive |

These are normally specialist services not offered directly by a print bureau. You should discuss your requirements directly with the service provider. |

For a list of what else to check before sending your file, such as making sure the scale of your model is correct, Shapeways have a good guide here.